Engine

THE ENGINE

Although the basic mill structure and machinery was restored within two years of the 1987 fire, a more long term problem prevented the use of the millstones. This was the low water flow in the river Ver.

The river Ver had once been a strong, powerful river, with many mills along its length all taking advantage of this ready supply of energy. The source of the river lay several miles beyond Redbourn supplying the water that flowed downstream eventually to join the Colne and then the Thames. For maybe one thousand years this stream powered the millstones at Redbournbury.

It is not known when the mill first started to suffer from the effects of the lower levels in the river, but by the turn of the twentieth century, the mill had been fitted with either a steam or gas engine. This was installed in an attempt to compete with the increasing threat of coastal, steam-powered, roller mills and to combat the slow demise of the river. Unfortunately the engine was scrapped at some stage during the First World War and few records of it still exist.

Ivy Hawkins continued to use the waterwheel and mill until the late 1950's, so clearly there was still sufficient water at this time to fill the leat, although probably only occasionally. Even in 1986/7 there was often a good flow in the river and the waterwheel could sometimes be turned (without the millstones).

After the 1987 fire, however, the situation went from bad to worse, enough flow to fill the river became rarer event, and eventually, in the summer of 1992, the river dried up completely.

This gradual decline of the river was due to several factors. The most significant was the installation of water pumping stations, from the mid-19th Century, all along the valley of the Ver and other Chiltern chalk streams like the Darrent and the Misbourn. With the increasing population and the building of many "new towns" after the second world war, water became an increasingly valuable commodity and demand rapidly increased. These pumping stations pumped water from below ground, usually at the head of the valleys and over many decades had the effect of reducing the natural level of the water-table. Springs began to dry-up and the amount of water entering the river decreased. The river was given a slight reprieve in 1993 when, after many years of campaigning and lobbying by the Ver Valley Society and others, the then National Rivers Authority (NRA) and the local water company introduced a scheme to reduce/cease pumping at a large station on the river. This had some effect on the recovery of the river, but demand for water still increases and the threat to many rivers increases with it.

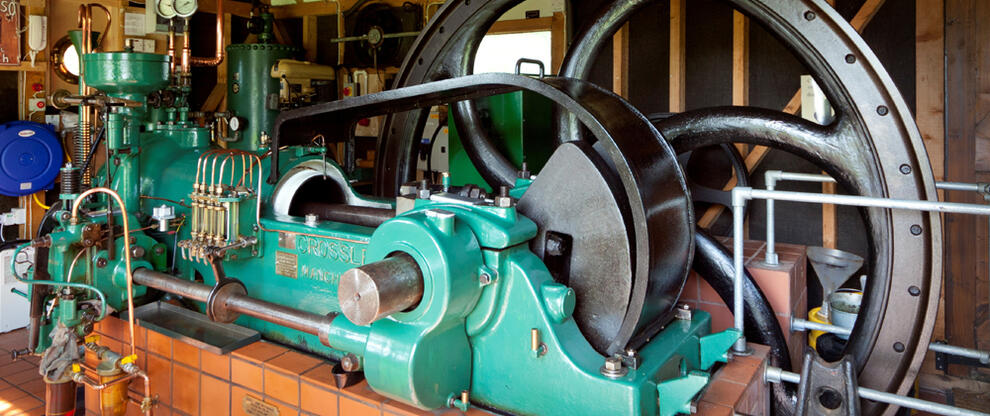

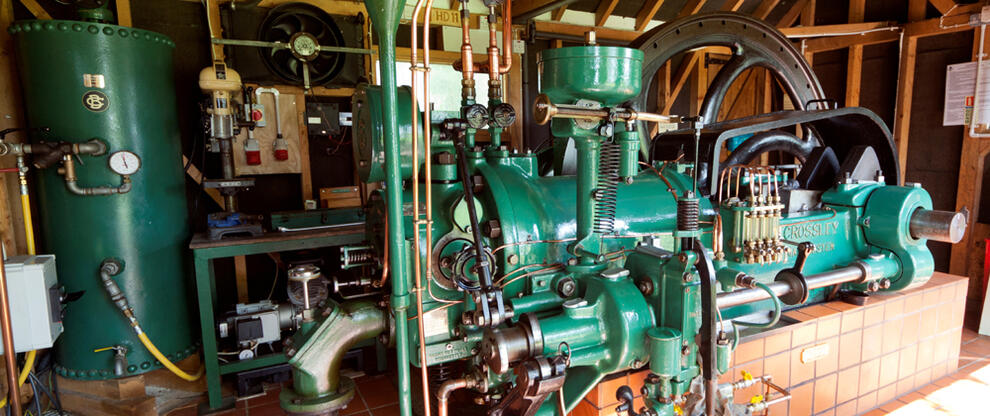

In 1995, the owners of the mill decided that for it ever to work regularly again, an additional source of power would have to be found. Many options were considered but eventually it was decided to find a replacement for the engine scrapped in ~1915. After some months, a suitable engine was found - still lying in an enthusiast's garden 30 years after being rescued from being scrapped from a water pumping station in Aldershot. A team of volunteers put in many hundreds of hours of work over eight months in 1996 and eventually it was restored to full working order to run for the first time in over 30 years on 4th September, 1996.

A further two years of work were needed before the engine was finally connected up to drive the mill, which has been achieved electrically:

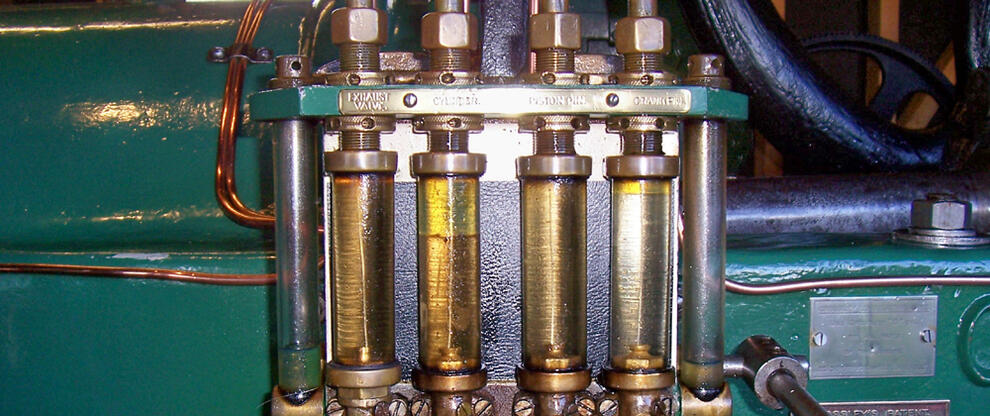

The engine has proved to be a popular attraction for visitors and has allowed the demonstration of the traditional milling equipment and methods. Its impressive specification is as follows:

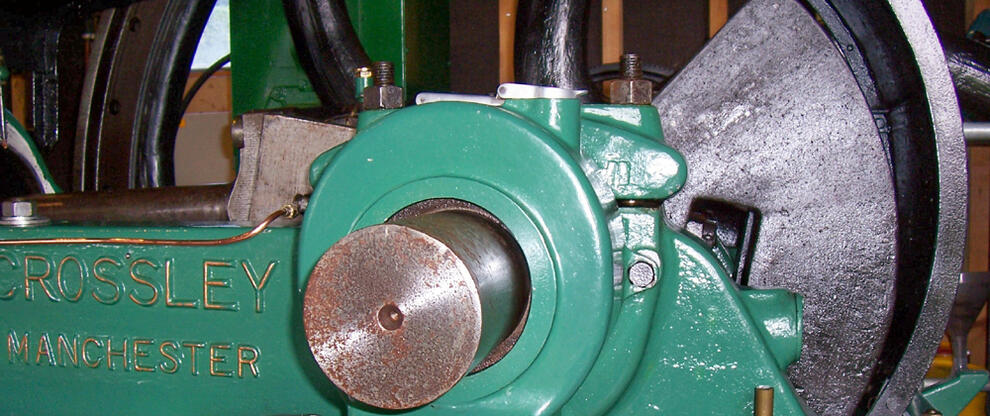

Crossley HD11 oil engine. Built 1932. Rated 55 b.h.p. @ 270 r.p.m.

Stroke 20", bore 11". Capacity 31 litres. Fuel Diesel. Flywheel 7'2" diameter.

Total engine weight ~4.5tonnes. Compressed air starting @300p.s.i.